Did you know that corrosion in metals can cost up to $2.5 trillion every year? Spending money on replacement materials can cost a business thousands, and so it makes sense to do everything that you can to prevent corrosion from occurring in the first place.

Instead of spending your money on replacing materials repeatedly, why not spend it on preventative measures to stop the metals from corroding in the first place?

If you don’t have to worry about metals in your manufacturing plant falling victim to corrosion, prevention is the best possible outcome. The good news is that there are plenty of ways that you can avoid corrosion with your metals and we’ve got some of the most effective ways listed for you below:

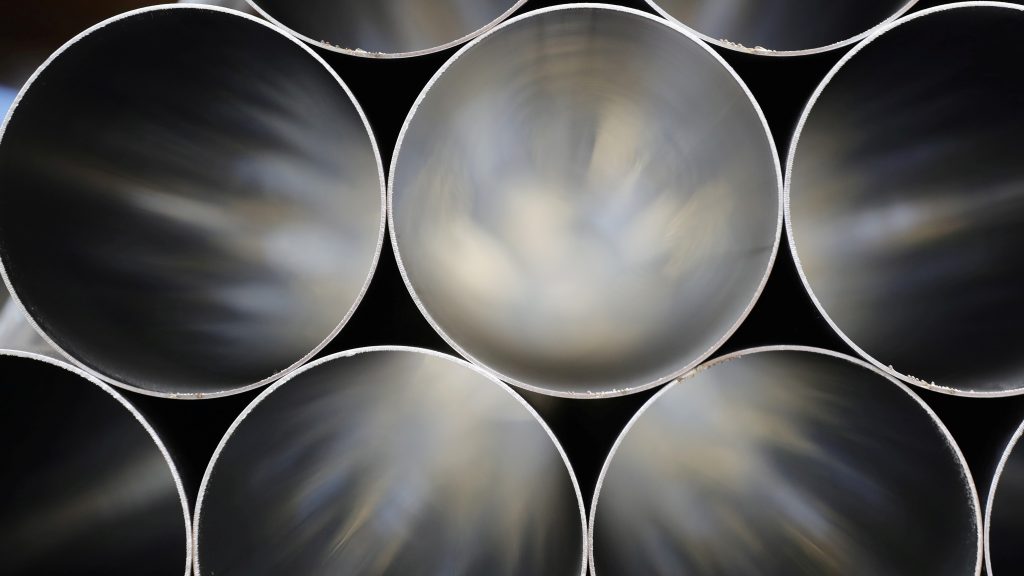

- Rethinking materials. Before you even start with preventing any corrosion, think about choosing materials that don’t rust or corrode in the first place. Aluminum and stainless steel, for example, are great options for corrosion-resistant materials. These are the metals that have the ability to stall the oxidation course, and you can stop the metals from rusting at all.

- Keep the metals away from the environment. You might already know that rust happens when metal hits air and water. Moisture in the air speeds up this process and if you want to avoid this you need to ensure that you store metals properly in the first place. Any contact with the air or moisture, and your metals will start to rust.

- Make sure that you have a topcoat. Most companies ensure that there is a polymer top coat when they are storing metals so that they don’t have to worry about oxidization. With a polymer, the metal is temperature-resistant up to 535 degrees F. It’s less expensive to add a topcoat than it is to replace all of the materials repeatedly.

- Anodic protection will help. Anodising the metals will help you to ensure that the metals are protected. It works very similarly to adding a topcoat, in that it can protect the outside of the metal and the anodic protection lasts a long time.

- Keep the metals clean. If you want to protect metals you need to ensure that they are regularly cleaned. These will ensure that you can prevent dirty water and dust build up. When you wash down metals with the right degreaser, or you sand it to a smooth finish, you can keep the metal clean and reduce the corrosion entirely.

When metal corrodes and rusts away, it can cost a lot of money to replace. When you are building something or creating parts, you need them to work for you.

They’re not going to work if they’re corroding too often. You have to take the right precautions to preserve the life of the metals and if you don’t know where to turn then it’s time to get your research going.

If you want your metals to be their best for production purposes, stopping them from rusting in the first place is a good place to start.