Tata Steel Hails Milestone As Contract Signed To Deliver Electric Arc Furnace

Tata Steel has signed a contract with a leading metals technology manufacturer to deliver a state-of-the-art electric arc furnace and additional advanced steelmaking equipment for its biggest UK site.

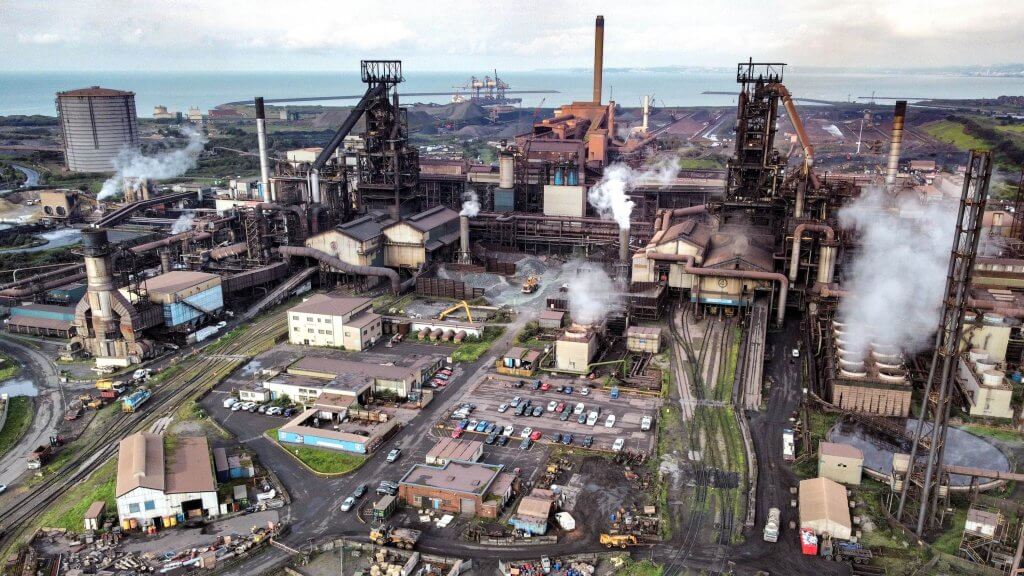

The company said the contract with Tenova marked a “significant milestone” in the switch to produce greener steel in Port Talbot, South Wales.

The electric arc furnace (EAF) is replacing traditional blast furnaces which have been shut down with the loss of thousands of jobs.

When it is commissioned from the end of 2027, the EAF will reduce the site’s steelmaking carbon emissions by 90%, equivalent to five million tonnes of CO2 a year.

Tenova will supply an EAF with an annual capacity of three million tonnes of steel – similar to the output of the site’s blast furnaces – by melting scrap steel sourced from the UK.

Mr T V Narendran, chief executive of Tata Steel, said: “This landmark agreement will enable us to transform our steelmaking site that will not only support the UK’s decarbonisation journey but also provide economic development opportunities for South Wales.

“Today marks an important milestone in making low-CO2 steelmaking a reality in Port Talbot as well as reducing the UK’s carbon emissions and supporting our customers with their own carbon reduction targets.”

Business Secretary Jonathan Reynolds said: “This partnership follows in the footsteps of an improved deal between the Government and Tata Steel, and is further proof of our commitment to a bright future for UK steelmaking.

“Technology like the furnaces made by Tenova is critical to decarbonising the industry, unlocking its potential to provide skilled jobs, and creating economic stability for future generations of steelworkers in South Wales.

“Our upcoming steel strategy will provide further certainty for the sector as we set out our plan for its long-term growth and viability, backed by up to £2.5 billion for steel.”

Paolo Argenta, executive vice President for the Tenova Upstream Business Unit, said: “We are working with Tata Steel UK at an unprecedented level of transparency and co-operation, and we are confident this will lead to a successful project implementation.”